Greenhouse lighting methods have been evolving through the years just as ventilation, shading, and irrigation systems have been evolving. However, many greenhouse growers have been "in the dark" about the advances in lighting technology. This is largely because greenhouse growers traditionally have viewed natural sunlight as the one resource that's free of charge. Growers typically adapted their production cycles to the intensity and availability of sunlight.

Those growers who tried working with supplemental lighting systems were limited to inefficient incandescent and fluorescent lights. However, the recent introduction of HID (high-intensity discharge) lighting systems into the market now presents growers with effective and efficient tools to boost production and profits.

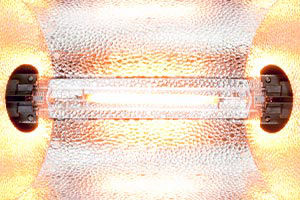

HID systems operate with a properly matched transformer, capacitator (some also require an igniter), and lamp, which consists of an inner arc tube possessing a chemical mixture.

The function of the transformer and capacitator is to take the input current and convert it, along with a starting pulse, into the specific operating voltage for each lamp. This process creates a very efficient and long-lived lamp.

The manufacturers of lighting systems are trying to get the word out on the continuing advances in HID lights and systems, but growers eager for knowledge often must rely on technical journals or "word-of-mouth," which sometimes takes on the weight of scientific truth without any research to back it. For example, most growers have the perception that high-pressure sodium lamps have rendered metal halide lamps obsolete. In fact, metal halide remains a very viable HID option, offering clear advantages over sodium in some cases. In some other cases, crops benefit much more from a setup that combines metal halide and sodium lamps than from a setup that uses only one or the other.

METAL HALIDE VERSUS SODIUM

Of the two primary types of HID lamps, metal halides have a more balanced spectrum, while sodiums emit more light energy in the yellow/orange/red region of the spectrum. Sodiums last longer and are somewhat more efficient when measured in "lumens per watt." However, controversy has arisen over the use of lumens as a measure for plant lighting efficiency. This is because the lumen (the flow of light equal to the amount of flow from a uniform point source of one candle) takes into account the human eye's sensitivity curve. Because plants respond to both visible and invisible light, other units of measurement such as micromoles (?mol/m?/s) or par value (photosynthetically active radiation) might be more accurate units of measurement when referring to greenhouse crops.

The other common measurement in the industry is the foot-candle, a unit of illumination equal to the amount of direct light thrown by one candle on a square foot of surface one foot away.

Because of their electrical efficiency (as measured by lumens per watt), sodium lamps have been the most common choice for greenhouse growers. However, the quiet evolution in greenhouse lighting has brought a number of options into the market. These include enhanced sodium types, as well as variations in the halide types. Among the halide types, for instance, are lamps with spectrums specifically suited to various plants. Another relatively new category of lamp is the conversion bulb. These bulbs can actually be screwed right into a fixture originally designed for one type or the other. Thus, a grower can switch from sodium to metal halide and back again.

None of these systems are cheap, and despite what you may have heard, there is no "one-size-fits-all" option. On the other hand, instead of settling for a system that might only partially and inefficiently meet your growing needs, you now have the opportunity to closely match specific growing objectives.

The broad rule of thumb I can offer (taking into account the HID systems currently available) are what I've gleaned talking to growers and horticulturists who have worked fairly extensively with greenhouse lighting.

* Sodium lamps are generally selected for photoperiod manipulation when a significant amount of daylight is also available.

* Because metal halide lamps emit light in a broader spectrum than do sodium lamps, some growers are using metal halide in conjunction with sodium for extending or augmenting natural light in areas where winter skies are often overcast. Plants grown solely under sodium lamps have a greater tendency to stretch than do those grown under metal halide lamps (which are richer in the blue spectrum).

* For the same reason, growers are selecting halides for propagation and foliage-only environments.

* Likewise, because halide lighting is more pleasing in light quality, it is often used in areas where workers spend a lot of time, or in situations where foliage and flower color needs to be as "natural-looking" as possible.

FIXTURES

After selecting the proper lamp type, avoid the temptation to skimp on inefficient fixtures, or those constructed of inferior materials. It is also important to factor in the shade that will be produced by the fixture.

In some fixtures, the ballast is mounted above the reflector. These types of fixtures cause less interference with natural light than do fixtures with side-mounted ballasts (or ballasts mounted behind the reflector). However, top-mounted fixtures are taller, which means they can't be used unless there is sufficient head room.

Fixtures also are now available with remote-mounted ballasts (transformer and capacitator), which eliminates the additional shading produced by fixtures with mounted ballasts. The other benefits to remote-ballasted units are the significant reduction in electrical installation costs and the much lower fixture weight.

PRICING HID SYSTEMS

When it comes time to actually price lighting systems, you'll find that the least expensive options are for 400-watt sodium or halide lamps and mounted ballasts. Prices per unit (lamp and ballast) can be under $200 each if ordered in quantity. Prices for 1,000-watt sodium or halide systems can approach $400 each. Costs increase with remote-mounted ballasts, special lamp types and voltages, and other options. On the other hand, these systems are built to last. For instance, the ballast electrical components are usually warranted for up to five years.

--- Peter Wardenburg is president of Hydrofarm Greenhouse Lighting, Petaluma, California.

Information:

Hydroponic Society of America

P.O. Box 3075

San Ramon, California 94583

Reprinted by permission.