The John E. Polk Correctional Facility (Seminole County Jail) is located in Seminole County in the town of Stanford, Florida, a suburb of Orlando. Originally constructed in 1980, was expanded to its present size in 1986. The facility is designed to house a maximum of 812 inmates, as of November 1, 1995, the average daily population is approximately 650. The facility is primarily utilized as a pre-trial detention facility, housing those inmates rendered by court order or arrest and either cannot make or have no bail set for them. Inmates who are sentenced to 365 days or less are housed there, with any person receiving more than 365 days being transported to the control of the State Prison System (Department of Corrections, State of Florida).

The idea of putting inmates to growing their own produce, was first put to serious thought while sitting at a Rotary Club luncheon with Sheriff, Don Eslinger. While discussing what I did as a consultant, the idea of Hydroponics was of great interest to the Sheriff, as a means of supplying work and food for the inmates in the confines of the jail, and also keeping security at a maximum. The Sheriff was very serious about this idea, so a meeting was set up and the wheels were set in motion.

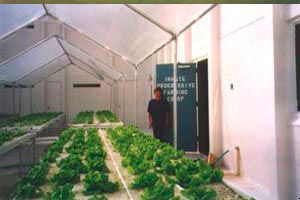

After several meetings and visits to the jail, plans were drawn for the Hydroponic project, which began on July 17, 1995. A 100 ft. x 60 ft. recreation yard within the confines of the jail was ideal for this. It was surrounded by 30 ft. high walls with an open end facing east. There were concerns about the lighting, but after several light meter readings, I felt there was sufficient enough light for growing several of the crops that the Sheriff had proposed to grow. As added insurance, it was decided to paint the walls and floor white so as to increase the light dramatically.

The next step was to cover the roof area to keep the heavy Florida rains out. A greenhouse contractor was chosen and a material was chosen that would allow the rain to create a mist in the area, as the area that had to be covered was almost flat. The diffusion of the rain would allow the rain to drain off the top of the greenhouse and prevent the roof from collapsing under the water weight. The material was pulled across the area and suspended on wire cable which were anchored on each side of the walls of the area.

Next came the building of trays and benches( the greenhouse contractor made up the benches and Ace Hydroponic trays were used for the Hydroponic system which I had decided to use because of several factors(one, the trays were made 24' long and 12" wide, four trays were used for each bench and all the trays interlocked together forming a 4 ft. wide bench. Each bench providing 96 sq.ft. of growing area. The total square feet of growing area once completed, amounted to approximately 2500 sq. ft.

When we came to the plumbing, we found that it was not possible to put an inground nutrient tank as we were within the confines of the jail, so a 350 gallon aquaculture tank was used, with a height of four feet. So as to facilitate our drain system, the benches were made 3' high so the nutrient was allowed to flow back to the tank. A low collective tank was considered, but this would have meant pumping the nutrient back into the main tank and adding to the expense and possibility of added maintenance. All of the irrigation system was installed by the inmates.

The tank was fitted with a top platform which held the main ¾ hp pump and the chiller. The chiller is a aquaculture chiller which sits on the platform and the cooling coil sits in the nutrient tank. The nutrient is drawn up the cooling coil tube and cascades out the tube top, performing two jobs, cooling the nutrient and also providing excellent aeration of the nutrient. The thermometer was set at 65 degrees which kept the tank cool and also helped to keep the chance of pythium, which is a common root disease in the tropics, at a minimum. The nutrient is fed through a 50 micron filter to the trays.

Once everything was set in place, an instructional seminar was given by me to the workers and supervisor chosen for this project. One of the first lessons to the inmates, were plumbing instructions and hands on help with the plumbing of trays.

Six women inmates were selected under the guidance of Ms. Betty Kelly, who was chosen as the Special Project Director. Betty has been with the Seminole County Sheriff's office for nearly 21 years. Originally from Charleston, West Virginia, she grew up on a farm and is now able to learn the modern future farming of "Hydroponics".

Betty has always been interested in Hydroponics, having first seen the Hydroponic display at Epcot. She finds this project a very exciting and challenging task, and in her words she quotes "it is a good feeling to reap what you sow". She finds it very rewarding to be able to teach the inmates how to farm hydroponically.

The first week of September the project was completed. The pump and chillers were tested, nutrient was pumped to the trays through Antelco drippers purchased from Australia. The nutrient ran through the trays down a 1 in 4 drop down the 24 ft. long trays. The nutrient was then returned to the main tank. This initial procedure was successful, so perlite was then added to the trays ready for planting. Ostinata lettuce was chosen for the first crop, and seeds were seeded into a 275 plug tray in sterile grow mix. The seeds were wet down, covered in a sheet of plastic and put into a refrigerator at a temperature of 65 degrees for two days.

The seed used was pellatised seed, meaning they were coated in a starch mixture for easier handling. After 2-3 days, the seeds had germinated and were then put into one of the trays with capillary mat instead of perlite. Here the seeds remained for ten days awaiting transplanting to the main trays.

The perlite system for growing the lettuce was chosen as this was the simplest method for the inmates to monitor, plus it would be a better method for growing cucumbers, tomatoes and squash, which would also be planted at a later date. After the perlite was placed in the trays, at a depth of 2", the system was turned on and nutrient allowed to flow into the trays.

The big day arrived, September 15, 1995 when inmates transplanted their first crop of lettuce into two benches (eight rows) of perlite. The transplants were planted at 7" intervals in the main trays, two sets of the four trays were to be planted on a daily basis, with a harvest date of approximately 25 days.

This was the day that Sheriff Don Eslinger had envisioned and dreamed of, which had now become a reality. Three local television stations as well as CNN News, and local newspaper reporters were there to record this moment in history for Seminole County. This was the first project in the U.S. where inmates in a jail were used in this new innovative method of farming, and growing the produce that they would later eat.

The lettuce transplants grew at a good rate, even though there were several heavy rains at this time of year, and poor light conditions. Several small problems arose, some leaks and dripper blockages, but these were corrected quickly.

October 24...harvest time! Again, the local news media were present to record this moment, and also CNN to complete their news story from beginning to end, which was later to air on television. 582 heads of lettuce was picked, weighing approx. 12 oz. each, and sent packing to the jail kitchen. By the end of October, Cucumbers and Cherry Tomatoes were planted, and in November, Bell Peppers and Squash.

This has proved to be a very successful project for the Seminole County Jail, and who are now looking at further expansion of this project.

The Seminole County Jail project is just one of the many interesting projects that I am involved in at this time. Upcoming projects involve a Hydroponic lettuce operation in the Cayman Islands, and an organic Hydroponic farm in Colorado which have plans to build a 44 acre greenhouse.